The Best Guide To Dust Extractor Vs Shop Vac

Wiki Article

The Basic Principles Of Dust Extractor Vs Shop Vac

Table of ContentsWhat Does Dust Extractor Vs Shop Vac Do?Some Of Dust Extractor Vs Shop Vac4 Easy Facts About Dust Extractor Vs Shop Vac ShownAll About Dust Extractor Vs Shop VacDust Extractor Vs Shop Vac for BeginnersRumored Buzz on Dust Extractor Vs Shop Vac

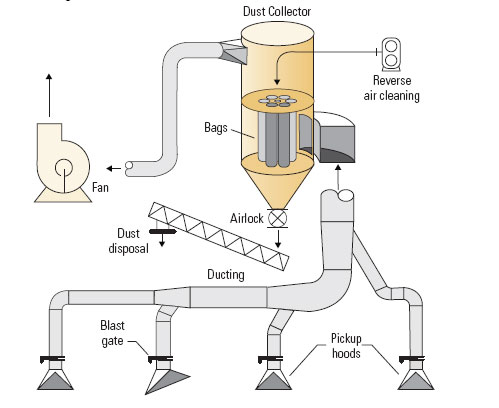

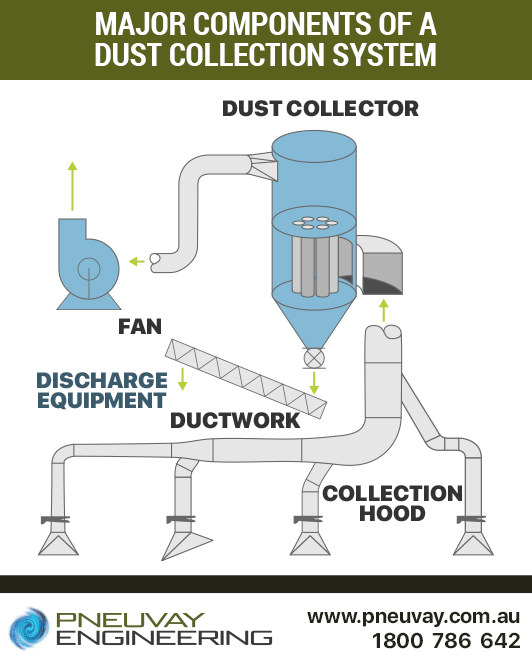

The obstacles for foundry dust collection systems focus on crystalline silica dirt, carbon monoxide gas, and also heat, which are hazardous mixes. These aspects make conference air quality requirements difficult and requiring. When picking a dust control system for a foundry, the very first factor to consider is the ability of the unit to endure extreme as well as unsafe office problems.Apart from the obvious conditions, the chosen equipment has to fulfill the policies of OSHA, the EPA, and the NFPA. To meet those standards, dust collection systems employ shakeout rooms, collection hoods, melt, mold pouring, cooling hoods, as well as exhaust stacks. Pleated bag as well as cartridge-style collection agencies have an extremely reliable filtering system as well as a portable size and decreased pressure drop.

Dirt collection systems for this kind of operation must be especially created to fit the type of coating being used. The function of the system is to control and also lessen overspray as well as dirt.

The Facts About Dust Extractor Vs Shop Vac Uncovered

It would certainly seem likely to increase air flow as well as activity, this type of option might be inefficient as well as waste power. The style of the cubicle relies on the pressure of the air entering the cell or booth. For many systems, it is essential to have a slight vacuum in the cubicle to avoid feasible positive pressure.One more approach is simply positioning the makeup air connection on the top of the booth. No matter of the layout, it is very important for the cleansing of the air to have cross air flow. Similar to a cleanroom, airflow in a thermal spray booth can be either horizontal or downward, though the descending layout is best for dirt collection systems. dust extractor vs shop vac.

The pharmaceutical industry is an extremely regulated sector with substantial and also specific policies. Dirt from pharmaceuticals is produced mainly during the production as well as product packaging of items - dust extractor vs shop vac. Each action of generating a medicine, which consists of granulating, drying out, blending, pushing, layer, and also grinding, creates huge quantities of dirt that require to be gotten rid of.

Some Known Factual Statements About Dust Extractor Vs Shop Vac

HEPA filters are frequently discovered in pharmaceutical dust control systems since they are the most efficient and reliable. Similar to a shop system, they are set up as a secondary protection to accomplish no emissions. Reusing creates a good image source deal of dirt as an all-natural result of lessening products to their basic materials.

Dirt stems after materials are shredded, squashed, or have paint or lacquer eliminated. All recycling centers are needed to abide by air top quality requirements. As they work to fulfill high quality criteria as well as control pollutants, they have actually recognized that dirt control is a major concern, resulting in the wide use dirt collection systems to alleviate and have the issue.

Some Ideas on Dust Extractor Vs Shop Vac You Need To Know

When manufacturers select a dirt control system, they are advised by producers regarding the kind of system that would certainly best fit their demands since purchasing as well as mounting a dirt control system is a significant financial investment. Particle matter is available in a wide range of forms, from silicon dust to wood chips as well as sawdust.Below is a list of the kinds of fragments that dirt collection systems can remove. Gypsum Gypsum find out here requires a high-efficiency baghouse system with the ability of operating at temperatures near 428 F (220 C). Felt Felt is utilized in clothing manufacturing and also needs dirt collection systems at 3 phases of the procedure.

Steel Chips Grinding procedures produce metal chips that require to be gotten rid of for the safety and security of employees. Baghouses as well as scrubbers are utilized for airflow filtering. Sawdust This is the most common great post to read material gotten rid of by dirt collection systems. Cartridge or baghouse techniques can be used, with baghouse being the most effective.

Dust Extractor Vs Shop Vac Things To Know Before You Buy

Material filter bags in a cartridge system are the most reliable method for gathering dirt. Dirt collection systems are covered to have the dirt and also clean the air.

With the introduction of dust collection systems, workers are more secure as well as more secured. Sugar Sugar dirt is the spin-off of the manufacturing of sweet. Pulse jet systems are utilized to keep the filters of the dust collection system particulate-free. The gathered material is removed and collected in drums. Zinc Zinc dirt is produced in the galvanizing process.

More About Dust Extractor Vs Shop Vac

A baghouse system is the favored system. Rice Dirt Rice dirt has extremely great and also minute fragments that accumulate during the production of rice-based products. A dirt collection system is needed for the defense and safety and security of workers. Silica Silica is among one of the most typical substances on planet. It is a main component of numerous manufacturing procedures, such as the manufacturing of glass, ceramic floor tile, cement, and asphalt.Report this wiki page